Talk to sales expert

Interested in one of the Aluminium solutions? Get in touch with our sales team to learn more.

SALES

Phone: +370 642 08498

Email: [email protected]

We develop aluminium solutions from scratch, if you have an idea or prototype or existing product, firstly let’s discuss your expectations, additional requirements or needs.

We analyze the purpose of use, aluminium profile design possibilities and how it can be fabricated efficiently.

Then we start profile multistage design process together with customer to achieve an optimal solution which solves the requirement.

After profile design is done, we order individually produced profiles and use our in-house manufacturing capabilities to produce highest quality products efficiently.

We supply components, or if needed we assemble the solutions and deliver the finished product to your warehouse.

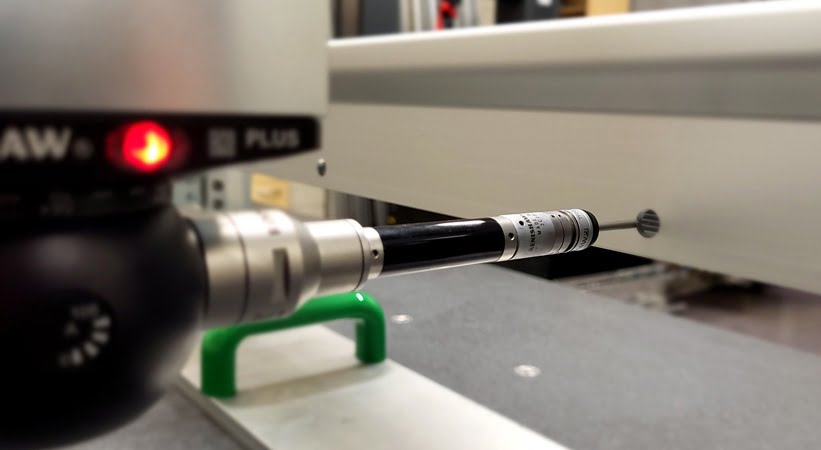

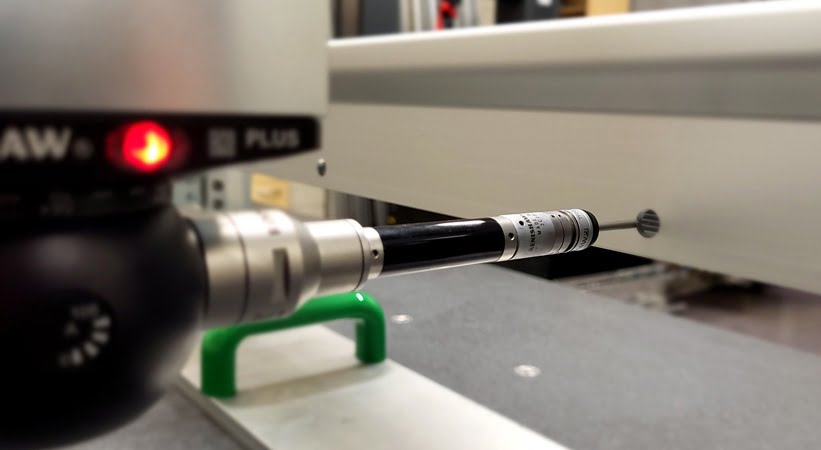

Middle and Long CNC

Short/long CNC manual and robot Feed

Interested in one of the Aluminium solutions? Get in touch with our sales team to learn more.

Phone: +370 642 08498

Email: [email protected]

Phone: +370 642 08498

Email: [email protected]